| Launch:2024-03-26 |

I. The principle of quantitative analysis of UV-vis spectrum

The UV-visible absorption spectrum is caused by the transition of valence electrons after the molecules (or ions) absorb ultraviolet or visible light (usually 200-800nm). Because the energy level transition between electrons is always accompanied by the transition between vibrational and rotational energy levels, the UV-vis spectrum shows a wide band .

The absorption spectrum reflects the absorption ability of molecules to different wavelengths of ultraviolet light. If an organic compound is irradiated with a beam of ultraviolet light with continuous wavelengths, some wavelengths of ultraviolet radiation can be absorbed by the molecules of the compound. If the absorbance of different wavelengths is recorded, the ultraviolet absorption spectrum of the compound can be obtained. Lambert-Beer's law is the basic law of light absorption, commonly known as the law of light absorption. Under certain conditions, the maximum absorption wavelength of the reference material can be obtained by measuring the absorption peak of the reference material and its corresponding wavelength. Then in the selected wavelength range (or the maximum wavelength), taking the concentration and absorbance of the standard solution as Abscissa and ordinate, the standard curve of the composite solution is drawn, and the corresponding mathematical equation is obtained. The content of the compound in the solution to be tested was calculated according to the standard curve equation.

Lambert-Beer's law:A=lg(I0/It)=εbc

A: Absorbance, describing the degree of light absorption of the solution.

B: Liquid layer thickness (optical path length), usually in cm:

C: The molar concentration of the solution, in mol/L.

ε: Molar absorptivity: unit mol ·L-1 cm-1; is numerically equal to the absorbance of the solution at a certain wavelength when the concentration is 1mol/L and the thickness of the liquid layer is 1cm.

2. Experimental samples

Verification standard solution: iron (44.8mg/L).

Reagents: reagent A, reagent B

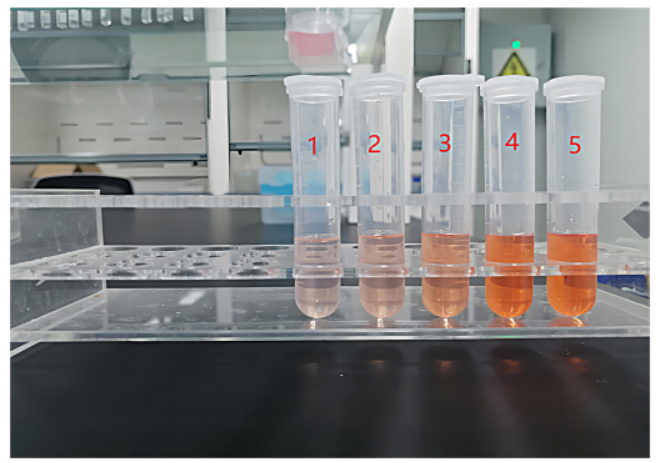

Fig. 1 sample diagram

1-0.448mg/L Fe+0.5ml reagent An and 0.5ml reagent B.

2-0.896mg/L Fe+0.5ml reagent An and 0.5ml reagent B.

3-2.688mg/L Fe+0.5ml reagent An and 0.5ml reagent B.

4-4.480mg/L Fe+0.5ml reagent An and 0.5ml reagent B.

5-5.376mg/L Fe+0.5ml reagent An and 0.5ml reagent B.

III. Experimental equipment

In the experiment, the samples are tested, and the equipment used is as follows:

Spectrometer MS11639-E40090093 (200-1100nm).

Light sources: HL10000-mini-D51010172.

Optical fiber: QP100-0.2-SRR-SS.

Sampling accessories: three-way liquid spectrum measuring cell, quartz colorimetric dish.

IV. Experimental methods

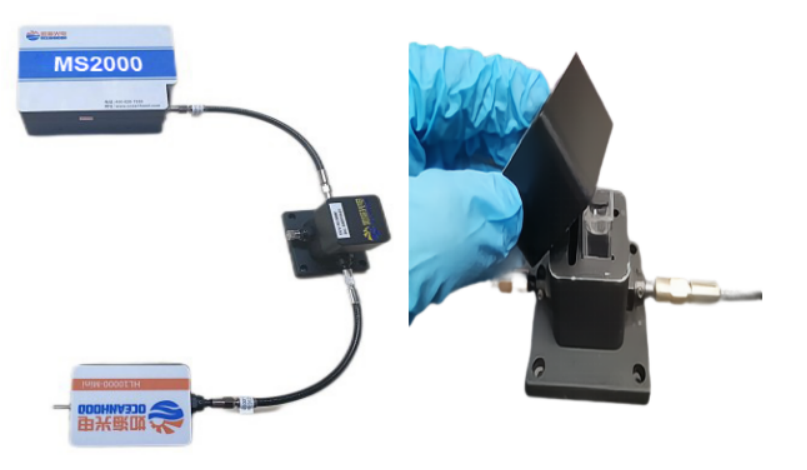

The light source is connected to one end of the liquid measuring cell through the optical fiber, the spectrometer is connected to the other end of the liquid measuring cell through the optical fiber, the spectrometer and the light source are plugged into the corresponding power adapter, and the data cable is connected to the computer.

The UV-vis spectrum collection process of the sample is shown in the following figure:

Figure 2. Equipment construction diagram

Iron: blank zero, take 10ml sample, add 0.5ml reagent An and 0.5ml reagent B, shake well, color for 5 minutes, collect absorption spectrum and record reading.

V. result analysis

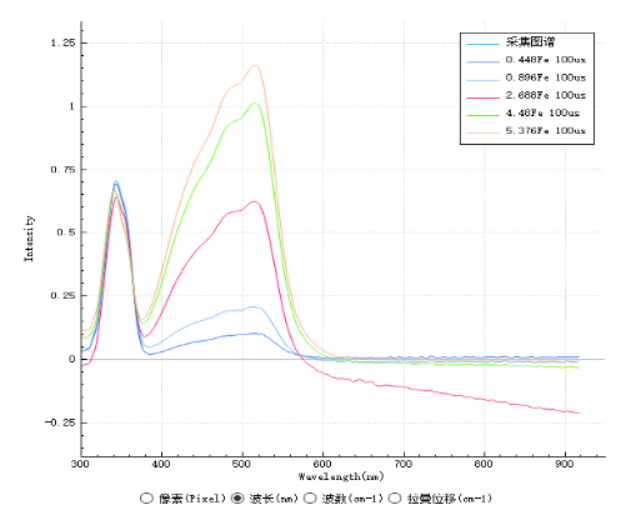

The collection map is as follows:

Fig. 3. UV-vis spectrum

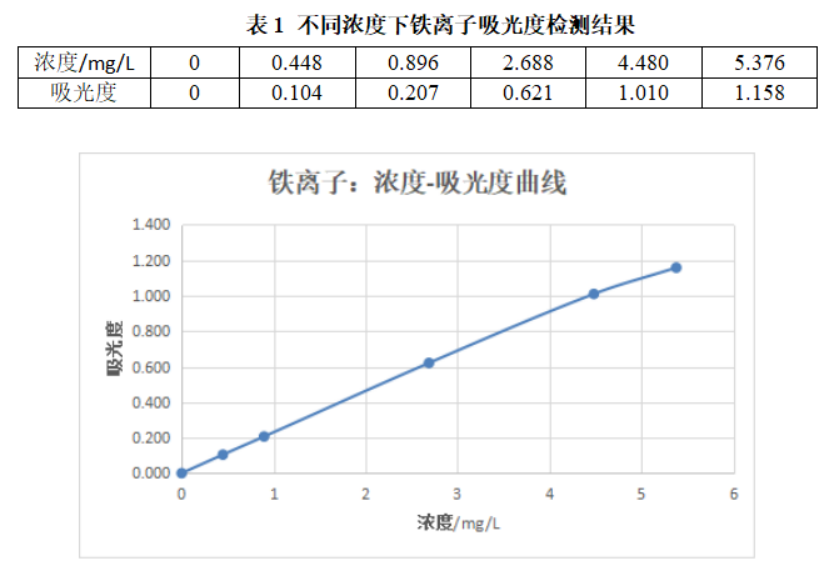

Select the characteristic peak of 516nm, select the concentration range that the absorbance increases with the increase of concentration, and draw the iron ion concentration-absorbance curve :

Figure 4. Absorbance curve

The linear segment fitting was selected to obtain the quantitative measurement concentration range of 0mg/L~4.480mg/L, and the linear equation of iron ion concentration-absorbance was yttrium 0.2259x0.0038pm R 2 ~ 0.9998.

Figure 5. Absorbance curve

VI. Experimental conclusion

In this experiment, iron ion was quantitatively detected by UV-vis spectrum, and the standard curve of iron ion concentration-absorbance was obtained by selecting the characteristic peak of 516nm. The range of quantitative measurement concentration was obtained by linear segment fitting. The range of quantitative measurement concentration was 0 mg ·L ~ (3 +). The equation of the standard curve was: y=0.2259x+0.0038. The detection results showed that there was a linear relationship between iron ion concentration and absorbance, and the sample concentration could be measured by spectral quantitative analysis.

VII. Instrument recommendation

The instruments used in this study are spectrometer MS2000 and continuous halogen tungsten lamp HL10000-Mini developed by Ruhai Photoelectricity Institute.

MS2000 refrigerated optical fiber spectrometer

MS2000 is an industrial-grade high-resolution micro-fiber spectrometer with compact equipment structure and configurable spectral range, high resolution, up to 0.07nm, low stray light, ~ 2 ‰, and small temperature drift. it is suitable for many industrial field measurements, such as laser measurement, plasma emission spectrum measurement, color measurement, absorbance measurement and Raman measurement. It is an industrial grade optical fiber spectrometer with high performance and price.

Product model | MS2000 |

Optical parameters | |

Optical fiber interface | Key-SMA905 |

Number of pixel channels | 2048 |

Stray light | ~2‰ |

Wavelength temperature bleaching | ~0.1pixel/℃ |

Consistency of optical fiber insertion and removal | ≦7% |

Functional parameters | |

AD sampling | 16 bit |

Data interface | USB2.0、RS232 |

Extended function interface | 24PIN |

Acquisition mode | Single, continuous, software trigger, synchronous external trigger, asynchronous reset external trigger |

Detector integration time | 50 μs-65 s |

CCD read noise1* | ≦30 |

CCD dynamic range2* | 3500:1 |

Signal-to-noise ratio | 380:1 |

Response linearity3* | ≥98% |

Weight | 630 g |

Dimension | 125×95×35 mm |

Operating temperature | 0℃~40℃ |

Working humidity

| 20%-85% |

*1:Integration time 10ms, root mean square of CCD readout noise *2:The CCD dynamic range is 2ms when the integration time is the saturation value/the root mean square of the CCD readout noise *3:Response nonlinearity is before calibration | |

上海如海光电科技有限公司400-820-7939